When facility processes include welding, effective fume collection and filtration are important to operational success and productivity. With the variety of welding techniques employed today, determining the ideal weld fume control method for your enterprise, can be a challenge. Should you use the source, ambient, or a combination of the two?

While both weld fume extraction approaches effectively filter air, in most situations, a source capture system is the first choice for collecting and controlling weld fume particulate. If overhead cranes or other conflicting conditions limit the suitability of source capture equipment, ambient control may be an effective alternative solution for weld fumes.

Before attempting to identify a weld fume extraction system for your organization, conduct a thorough review of your facility, processes, and worker requirements. This will help you better identify a weld fume extraction solution that meets your operation’s needs.

Production Materials

What types of materials are being welded?

Production Volume

What is the rate of fume generation? How many stations are active? Is welding consistent throughout the day or intermittent?

Work Cell Layouts

Is the area open or divided into individual cells?

Worker Movement

Is the welder stationary or moving around the item being welded?

Production Area

Are there physical space limitations due to structures or overhead cranes?

Welder Preference

Are workers willing to use a capture hood or a portable system?

Space Flexibility

Is it important to have the ability to rearrange work cells?

Consider Source Control Methods

As its name implies, source capture means the weld fumes are collected at – or close to – their point of origin. With this setup, a close-capture weld fume hood is strategically placed to extract the weld fumes prior to it reaching the welder’s breathing zone, and well before weld fumes are dispersed and diluted throughout the air in the facility.

Source capture is widely considered the method of weld fume collection because it focuses on the fumes at their point of generation, utilizing smaller air volumes to control contaminants before they further circulate.

There are multiple means for effective source capture including stationary weld fume hoods, extraction arms, and downdraft benches. If the work performed in a specific area is consistent, a properly located fixed weld fume hood would be the ideal solution. If the area is used for different work or applications, a versatile extraction arm can offer valuable maneuverability. And if the weld requires movement around the source, a downdraft bench may be an appropriate option.

When properly designed and installed, source-capture weld fume extraction systems can effectively collect the fume produced in most industrial settings. Having a thorough understanding of the processes, contaminants, and working practices will help ensure performance expectations are met.

Advantages

- Minimizes weld fume concentration entering workers’ breathing zone.

- Reduces the spread of contaminants throughout the facility.

- Utilizes smaller air volume to effectively control contaminants.

Challenges

- Stationary collection points (e.g., hoods) might be difficult to use based on plant or workstation configuration

- Portable equipment may be inconvenient for welders to have to continuously move on larger projects

- Relocating pick-up points and fume collection equipment can be time-consuming

You May Like...

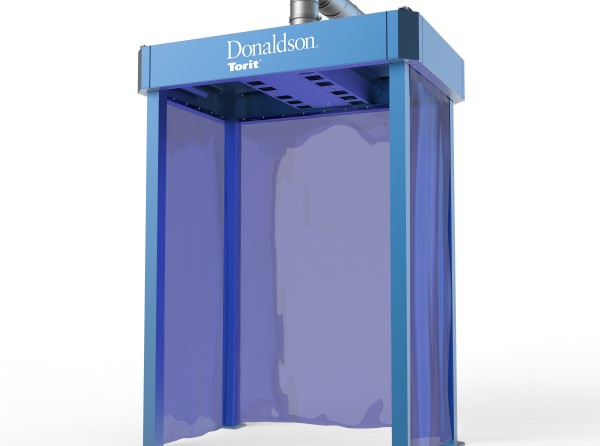

Consider Ambient Control Methods

Unlike source capture, ambient control methods utilize the facility’s natural air movement to promote the filtration of the overall air volume in the facility, controlling average overall concentrations of weld fumes in a work area. Mitigation strategies that include ambient collection are intended to help process owners manage weld fumes in a facility by providing air exchanges at regular intervals.

Maintaining consistent and predictable air movement throughout the designated work zone is critical for effective ambient collection and filtration. Identifying airflow patterns in your operation using a visual modeling tool and imagery assists in collector placement throughout the facility.

Because weld fumes naturally rise — typically 10-15 feet above the shop floor — the air intake should be placed at that level. Returning filtered air near the floor level helps support the natural circulation in a facility.

Ambient collection may be an appropriate solution if weld stations or work areas in your facility are frequently altered to accommodate different projects. When utilizing an ambient weld fume extraction system, it’s common to have multiple in-take and exhaust locations. The number of collection points required for proper filtration is determined by the size of the work area, the rate or duration of welding, and the actual application or type of welding being conducted.

Advantages

- Enables easy repositioning of weld stations for various applications.

- Configurable for challenging facility layouts.

- Effectively supplements source-capture equipment.

Challenges

- Manipulating weld fumes that circulate beyond the natural boundaries of the workstation.

- Natural ventilation, such as windows and doors, may impact airflow patterns.

- Changes in productivity schedules can require additional collectors to meet initial filtration performance requirements.

You May Like...

Regardless of the system you select, proper dust collection for weld fume management is only one aspect of your overall mitigation plan. As you initiate discussions about your facility’s unique weld fume mitigation strategies — and the viability of these distinct solutions — we recommend consulting a dust collection professional and your local Authority Having Jurisdiction.

Donaldson’s comprehensive dust control solutions help process owners effectively address their dust, fume, and mist collection challenges by providing knowledgeable guidance, industry-leading equipment as well as unrivaled aftermarket service and support.

Backed by more than 250,000 global installations over 50 years, and a select network of partners, no other manufacturer is more capable – or more trusted – to solve your dust, fume, and mist collection challenges than Donaldson. With our customer-inspired consultative, comprehensive and connected approach to dust, fume, and mist control, Donaldson is with you every step of the way.

From Weld.com: Welding any pass produces fumes so have fume extraction in place like the Easy-Trunk from Donaldson.

When putting in a root pass, your heat can change the way your weld is going in but one thing that stays consistent is the amount of fumes you are putting off. It is a great idea to have some fume extraction in place like this Easy-Trunk from our friends at Donaldson.

This video is used with permission from Weld.com. The views and opinions expressed in this video are those of the original creators and do not necessarily reflect the views and opinions of Donaldson.