Welding is an industrial process that involves melting two pieces of metal together. Welding also produces harmful fumes and gases that can be hazardous to the health of the welder and others in the area. Weld fume hoods are a critical safety device that can help to protect workers from harmful fumes and gases.

Welding fume extractors or welding fume hoods are devices that remove harmful fumes from the air around a welding operation. Welding fumes are a mixture of gases and particles that are released when metal is melted and fused. These fumes can contain a variety of hazardous substances, including metal oxides, nitrogen oxides, and carbon monoxide. A recent evaluation by IARC shares that welding fumes and UV radiation from welding are classified as carcinogenic.

Welding fume extractors work by drawing the fumes away from the welder's breathing zone and into a filtration system. The filtration system removes the hazardous substances from the fumes, and the clean air is then returned to the work area.

Benefits of Welding Fume Extractors

- Reduced exposure to hazardous fumes — Welding fume extractors can significantly reduce the volume of hazardous fumes that welders are exposed to. This can help to protect welders from a variety of health problems, including respiratory problems, cancer, and neurological disorders.

- Improved air quality — Welding fume extractors can improve the air quality in the welding workplace. This can benefit both welders and other workers in the area, as well as customers and visitors.

- Increased productivity — Welders who are not exposed to hazardous fumes can work for longer periods of time without experiencing fatigue or discomfort. This can lead to increased productivity.

- Reduced downtime — Welding fume extractors can help to reduce downtime due to health problems caused by exposure to hazardous fumes.

- Compliance with OSHA regulations — Welding fume extractors are required by OSHA in many industries. Using a welding fume extractor can help businesses to comply with these regulations and avoid costly fines.

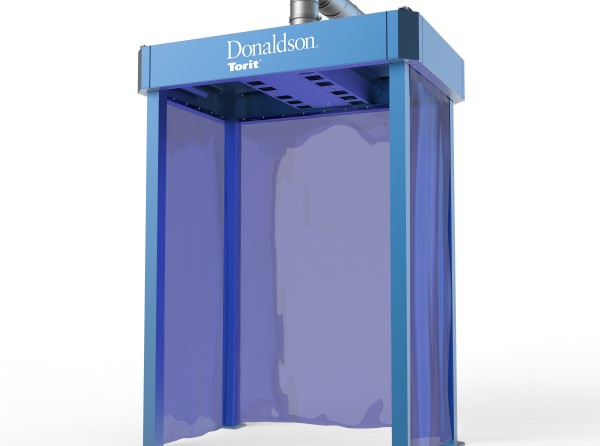

Donaldson’s Torit® Fume Hood provides fabricators with multiple fume extraction capabilities. Welding operations are expanding, and along with it, the need for flexible workflows and safe workplaces. Designed for robotic or manual welding applications, the Fume Hood’s low-profile allows for a more flexible installation than traditional canopy-style hoods. When paired with the optional weld curtains, it can be sized to reduce airflow requirements, ultimately lowering the overall cost of a filtration system.

The Torit® Fume Hood can be easily integrated with an existing system or paired with a Donaldson cartridge collector for enhanced filtration. It also comes in multiple sizes and is available in free-standing and ceiling-mounted configurations for better integration into facility workflows.